The Robotics Threshold: China's Rise, America’s Reckoning

Navigating the Robotics Revolution, Supply Chain Sovereignty, and the Future of Global Power

Introduction: A Grand Arc of History

Last month, my SemiAnalysis contribution illuminated a critical inflection point in the global technological landscape. The analysis revealed China's systematic ascension to robotics leadership while the United States continues to experience the erosion of its industrial foundations. This divergence represents not merely a technological gap but a fundamental strategic vulnerability with far-reaching implications for economic sovereignty and national security. This context frames our current deep dive into a transformation that will reconfigure the global order and redefine the parameters of geopolitical power.

The robotics revolution underway represents the single most radical transformation in human history – one that heralds the dawn of a new era where automated labor will redefine the very fabric of our civilization. Contemporary robots are achieving breakthrough capabilities in adaptability, precision, and autonomous decision-making, decisively challenging our bedrock assumption that human physical labor remains indispensable to manufacturing. Just as the internet rewrote the rules of information exchange, truly capable robots will overhaul production lines, revolutionize supply chains, and reconfigure urban landscapes. Factories will run 24/7, cities will evolve to integrate autonomous systems, and every aspect of society – from labor value to power dynamics – will be fundamentally reimagined as fully realized industrial automation becomes operational.

This technological threshold creates a stark strategic dichotomy between nations. Those achieving self-sustaining automated production ecosystems will experience unprecedented prosperity, while those failing to cross this threshold face irreversible subordination. China's forward-looking industrial policy and systematic investment in automation technologies have established a formidable foundation for robotics leadership. In contrast, the United States appears to be on a precarious path, with its manufacturing capabilities gradually declining amid regulatory fragmentation and geopolitical missteps. Without a major course correction, America risks devolving into a state of everlasting dependency, forced to rely on other nations that control the critical supply chains and technologies of the future.

Crossing this technological threshold is less an option than a strategic imperative. It marks the boundary between autonomy and dependency.

Yet opportunities remain for the United States. As the historical epicenter of industrial transformation and the beacon of Western civilization, America possesses unique regenerative capabilities. From the Manhattan Project to Silicon Valley's emergence, the nation has demonstrated exceptional capacity for technological mobilization and systemic reinvention. By reimagining its industrial foundation and embracing comprehensive transformation, the U.S. can reclaim its position as a primary architect of the emerging technological paradigm rather than a peripheral participant. This is not merely an economic imperative, but our profound duty to future generations: a chance to build a legacy that secures prosperity, autonomy, and continued leadership through the same fearless determination that has characterized American progress.

The path to renewal presents formidable challenges. The window to secure a foothold in the automated world is rapidly closing, and today’s inaction will lead to centuries of inescapable supply chain dependency. The transformation ahead will be neither gradual nor forgiving – it demands bold sacrifices and strategic realignments that few are willing to face. Failure to address structural vulnerabilities will relegate the United States to a subservient position in a global hierarchy increasingly dominated by automated labor. Our duty is clear: to confront this pivotal moment with determination, to secure a better world for those who follow, and to ensure that our legacy embodies resilience, innovation, and strategic autonomy.

Contents

This article delves into the evolving robotics ecosystems of the world's two leading technological powers, the United States and China, analyzing their divergent paths and outlining a strategic imperative for American adaptation and leadership. We explore the forces shaping this critical juncture and present a potential roadmap for securing America's future in the dawning era of automated labor

The Inevitable March of Automation: Examining the nature of the unfolding robotics revolution and its profound, civilization-altering implications.

China's Rise to Robotics Dominance: Analyzing the sources and signs of China's success in building a formidable robotics ecosystem poised to reshape global industry.

America's Great Stumble: Investigating the structural weaknesses, strategic missteps, and cultural factors hindering the United States' progress in robotics.

The Last Window: Why Hope Remains: Assessing the potential for American renewal, the urgency of the current moment, and the stakes involved in seizing the final opportunity for leadership.

The Path Forward: Securing America’s Future in Robotics: Outlining a multi-phase strategic framework designed to enable the United States to achieve supply chain sovereignty and lasting prosperity.

Let’s begin by exploring the fundamental drivers and consequences of the automation wave that is already starting to reshape our world.

I. The Inevitable March of Automation

We stand at the threshold of a transformation unlike any other in human history. The advent of true robotics signals not merely an advancement in technology, but the dawn of an era defined by automated labor. This shift, driven by converging breakthroughs in artificial intelligence and physical systems, carries an unstoppable momentum that transcends the control of any single nation or entity. It promises to dismantle age-old constraints on productivity and fundamentally reorder the global balance of power. Understanding the nature of this revolution – its roots, its profound impact, and the choices it presents – is paramount for navigating the turbulent waters ahead and securing a future in the automated world. The stakes are existential, and the trajectory of civilization hangs in the balance.

1. The Dawn of True Robotics

Humanity has chased the dream of automation, beginning with the industrial robots of the 1960s that transformed car factories. Mechanical arms welded and painted with precision, yet they remained tethered to rigid scripts and controlled environments. Later, ambitious projects like Honda’s ASIMO and Boston Dynamics’ Atlas showcased humanoid robots walking and leaping, while self-driving ventures from Waymo and Cruise promised autonomous navigation. These efforts, though groundbreaking, delivered only partial autonomy – brittle imitations of the adaptable, general-purpose machines envisioned as true robots. Each advance fell short of replacing a human worker in dynamic, unstructured settings, leaving the field mired in compromises.

The barriers to true autonomy were steep and multifaceted. Hardware posed relentless challenges: sensors lacked the finesse of human perception, with vision systems struggling to gauge depth and tactile arrays failing to mimic touch. Actuators, the muscles of robots, were caught in a bind – hydraulics offered power but burdened machines with weight while electric motors sacrificed strength for efficiency. Software lagged even further, relying on rule-based systems incapable of navigating real-world complexity. Furthermore, the absence of industrial standards for components and interfaces created significant integration challenges and hindered the development of a scalable ecosystem, creating a formidable distribution barrier that kept robots behind safety cages, far from widespread deployment.

A true robot is a machine that can perform one human unit of work. This definition requires General-Purpose Mobile Manipulation (GPMM) – the ability to both navigate and execute diverse tasks in unstructured environments with a single, versatile physical platform.

Today, those barriers are crumbling under a convergence of breakthroughs. Sensor technology now rivals human senses with high-resolution vision and delicate tactile systems emerging from labs into production. Electric actuators have evolved, blending power and efficiency through advanced materials and designs. Physical AI integrates perception, reasoning, and action into adaptive intelligence. Standardization efforts are coalescing, enabling mass production and driving costs down. This shift marks a decisive leap from partial autonomy to the brink of a true robotics industry, where machines can finally step out of controlled settings and into the unpredictability of human spaces.

This pivotal moment signals the birth of the true robotics industry. True robots fuse locomotion and dexterity to transform any human-centric environment into their workplace, performing the full spectrum of human work without requiring radical modifications. Within years, they will flood factories, warehouses, and households as genuine, drop-in replacement for human labor. This is not an incremental step but a revolutionary leap toward machines capable of matching, and potentially exceeding, our own physical capacity. The implications are profound: a world where automation is no longer a dream but a reality, poised to transform every corner of civilization. This is the dawn of an era we can no longer delay or deny.

2. The Profound Impact of Automation

Throughout human history, four fundamental scarcities have constrained civilization's development: raw materials, labor, energy, and technology. While we've made incremental progress in managing these limitations, none has ever truly been overcome. Today, we stand at the threshold of dismantling one of these foundational constraints – the scarcity of physical labor. The robotics revolution marks the first time humanity has gained the capability to fundamentally transcend a core limitation that has shaped every aspect of how societies organize and operate. The transformation we're about to see isn't just another technological boom; it is a radical overhaul that rewrites the very definition of productivity and realigns every aspect of society around autonomous capabilities.

Power comes from dependencies. It is rooted ultimately in the foundational scarcities of materials, labor, energy, and technology.

Productivity will leap beyond traditional boundaries. Factories will operate ceaselessly with relentless precision, unbounded by human schedules or the fatalities of aging workforces. Manufacturing will detach from demographics and thrive in nations with dwindling populations as easily as in those with abundant labor. Urban landscapes, once designed for human routines and car-driven logistic, will evolve to embrace autonomous systems like delivery drones and robot maintenance crews. Supply chains will grow leaner and more resilient as robots streamline every step from creation to distribution. Civilization will pivot from reliance on human effort to the power of automation, rewriting the rules that have governed progress since the first tools were forged.

This shift will reshape power and dependency on a global scale. As robots emancipate humanity from manual labor, autonomous capabilities will emerge as the new currency of influence that determines which entities dominate the future. Those who harness the full potential of robotics will wield unprecedented control over goods and services, while those who do not will slip into inescapable subordination to the output of automated powerhouses. New groups will rise to prominence by leveraging this technology to challenge entrenched elites. Existing power structures that fail to adapt to this new reality will see their authority erode. The world will tilt toward a new equilibrium defined not by human hands but by machine precision.

Automation signals more than industrial change – it heralds a societal overhaul where cities, supply chains, and power itself are redefined by machine capability.

We are entering a new era of automated labor and machine-driven productivity. This isn't a gradual evolution of existing technology but a systemic transformation that dissolves the bedrock assumption underlying our civilization: that the world requires human physical involvement to operate. When robots can genuinely match human adaptability across unstructured environments, they trigger a reset that reaches far beyond factory floors into the very foundations of economic and political power. This inexorable momentum will impact every individual, every business, and every nation, forcing us to reconsider the fundamental aspects of humanity in a world where physical contribution is no longer a defining necessity. The world as we know it is about to change forever.

3. The Looming Technological Threshold

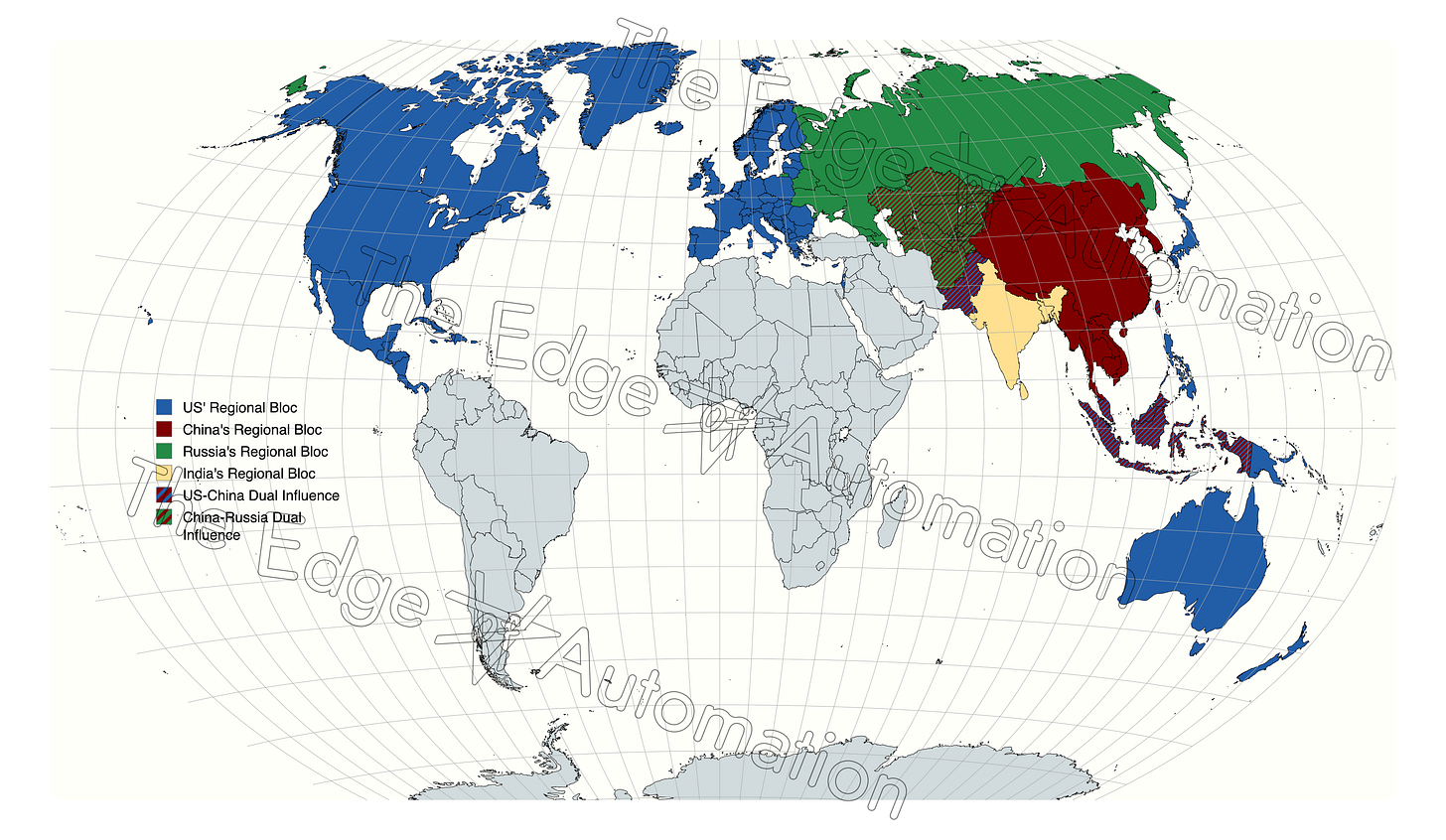

The robotics revolution is unfolding within a shifting global landscape characterized by the interplay of rapid technological advancement and intensifying geopolitical competition. The post-Cold War era of unchallenged American hegemony is giving way to a multipolar world, with nations realigning into regional blocs and prioritizing national interest, supply chain resilience, and strategic autonomy over ideological alignment. At the heart of this dynamic is a fierce race for technological supremacy, with robotics and automation emerging as the decisive battleground.

What makes this era distinct is the looming technological threshold that threatens to permanently divide nations into those that control the core technology and those who do not. Mastery of advanced robotics will separate global leaders from those relegated to the sidelines. Success requires more than just hardware innovation, but demands the creation of comprehensive ecosystems that nurture the true robotics industry – one that integrates AI with manufacturing to automate entire supply chains. Nations that cross this frontier will redefine productivity and liberate their economies from the constraints of human labor. Those that lag behind risk dwindling economic prospects and waning geopolitical influence.

The robotics threshold represents an irreversible sorting: nations achieving automation supremacy will lead, while laggards face inescapable dependency.

Nations that harness the full power of robotics will enter a new golden age. Manufacturing will rise to unprecedented levels of productivity, while supply chains become resilient against disruptions, labor shortages or demographic decline. New industries – such as automated maintenance and AI-driven design – will emerge to support this monumental shift. This leap will not only bolster domestic sectors but also empower these nations to control the flow of goods and services, firmly establishing them as the power centers of the new global economy. Their automated systems will underpin global supply chains, and their unmatched productivity will be indispensable in a world increasingly reliant on machine-driven output.

Conversely, nations that fall short of this technological threshold face a grim future of escalating dependency and potential stagnation. Unable to compete with the efficiency and scale of automated economies, their domestic industries risk becoming uncompetitive and obsolete. They may find themselves relegated to the role of low-value resource exporters, perpetually reliant on the technologically advanced nations for manufactured goods, critical infrastructure, and essential services. This dependency threatens to become a state of perpetual subordination, locking them out of the primary value-creation cycles of the new era and limiting their capacity for self-determination.

Mastery of robotics is no longer just a competitive advantage; it is the threshold dividing nations into architects of the future and those relegated to perpetual dependency.

This divide dwarfs past technological shifts. Automation’s productivity gap is so vast it could lock nations into permanent tiers of leaders and followers with little chance of crossover. Breakthroughs in AI and robotics are accelerating this split, while geopolitical moves – such as China’s massive investments in automation – further widen the chasm. Survival demands not just maintaining a competitive edge but also the ability to operate and thrive in a world where automated capabilities determine strategic relevance. The momentum toward future is accelerating and the choice is clear: automate or fade. Decisions made today will determine on which side of the looming threshold nations will stand tomorrow.

4. Winners and Losers in the New World Order

The coming wave offers no middle path. It creates a binary future: those who master robotics will shape the new civilization that emerges, while those that lag will sink into dependency and decline. A country's fate hinges solely on its ability to automate manufacturing and supply chains. The resulting productivity gap will be vast and unbridgeable. Control over robotics technology will yield global influence and self-sufficiency, while delays cost competitiveness and force nations to rely perpetually on others for vital goods and technologies. The world will be divided into a few winners and many losers, with no path in between.

Control over automated production is the new determinant of national sovereignty and global standing, deciding which powers rise and which irrevocably decline

China commands this race through a decade-long focus, unwavering determination, and relentless execution. Its robotics ecosystem is unrivaled, likely boasting more companies than the rest of the world combined. China’s blend of advanced AI and vast manufacturing speeds up progress, while its aggressive deployment generates data that fuels continuous innovation and rapid industry growth. Its robust supply chain delivers resilience and cost efficiency for this emerging industry long before other nations have fully embraced robotics. Chinese firms produce high-quality robots at low costs, compelling even U.S. companies to rely on their components. Strategic government subsidies and strong state-civil alignment further amplify this advantage, driving swift robotics deployment and solidifying China's lead. This industrial depth provides a powerful foundation for leadership in the automated era.

The United States, once a technological trailblazer, now grapples with steep challenges in this revolution. Its robotics ecosystem lacks the depth and unity of leaders, diminished by decades of offshoring and slow industrial revitalization. Infrastructure deficits and a shortage of skilled workers compound the problem. Without a bold strategy to rebuild manufacturing and foster a cohesive robotics industry, the U.S. risks falling behind, undermining its economic security and developing serious dependency on other automation front-runners. Time is of the essence as the global race intensifies. America's choice today will echo for generations, determining whether the U.S. can reclaim its position or slide into obscurity.

The productivity gap created by automation threatens to lock nations into permanent tiers. Decisions made now will echo for generations.

The stakes extend far beyond simple economic competitiveness. The ability to control and produce critical goods will define future geopolitical power. Nations that fall behind in the robotics revolution risk being relegated to the role of perpetual dependents, forced to import the very technologies that will shape the post-reset civilization. In this new order, power and wealth will be determined not by traditional resources, but by the capacity to innovate, scale, and deploy autonomous systems.

The march of automation is an inexorable tide, sweeping away the foundations of a world built on human labor. Barriers once thought unbreakable have fallen, unleashing machines that rival our own capabilities. This revolution will redraw the lines of prosperity and power, creating a global order where only a few will thrive. China has seized the lead, its robotics ecosystem a testament to strategic vision, while the United States grapples with a faltering footing. In the next section, we delve into China’s rise to dominance, uncovering the forces behind its success and the urgent lessons it offers a world on the brink.

II. China's Rise to Robotics Dominance

China’s ascendancy in robotics is redefining the global technological landscape. In this section, we survey its remarkable journey, from pioneering breakthrough technologies and a rapidly maturing robotics industry to the creation of a dynamic, largely self-sufficient ecosystem underpinned by a powerful state-civil harmony. We outline how China’s strategic investments in AI, comprehensive supply chains, and coordinated geopolitical efforts have positioned the nation to usher in an era of unparalleled productivity and a leap toward artificial general intelligence (AGI). This integrated approach not only sets China apart but signals a transformative golden age on the horizon.

1. China is Living in the Future

China's journey into robotics is not a distant projection but a present-day reality reshaping its industrial and societal fabric. While other nations debate the future potential of automation, China has already crossed a critical threshold, deploying robots at an unprecedented scale and sophistication. In 2022 alone, China installed over half the world's industrial robots and solidified its position as the dominant global market. Robot density in its manufacturing sector now dramatically outpaces the global average. This is not merely about industrial arms in cages but the emergence of versatile, AI-driven machines operating in complex environments, signifying a lead that extends far beyond sheer numbers into the realm of true automation.

This transformation is starkly visible in China's burgeoning "lights-out" factories. Facilities like Xiaomi's smartphone plant in Beijing and Foxconn's Shenzhen complex operate almost entirely without human intervention. Networks of robots, automated guided vehicles, and AI monitoring systems manage production around the clock, from component assembly to quality control and even autonomous cleaning. These 24/7 operations achieve staggering efficiency, boosting output significantly while slashing labor costs and minimizing errors. This level of automation sets new global benchmarks for productivity and cost efficiency, giving Chinese manufacturing a formidable competitive edge built on relentless machine precision.

Parallel advancements are occurring in China's military modernization efforts, where advanced, AI-driven robots enhance defense capabilities. Unmanned ground vehicles, like the Sharp Claw, patrol sensitive borders autonomously, navigating harsh terrains. Quadruped robots, such as the Unitree models, provide reconnaissance in complex environments, responding to voice commands and tracking objects in real-time. Sophisticated drones, like the Wing Loong, execute surveillance and precision strike missions with minimal human oversight. This integration represents a strategic shift towards force multiplication, reducing human risk and enhancing operational effectiveness through intelligent autonomous systems.

Video: The Rise of China’s Military Robots

Beyond industry and defense, China is integrating robotics into the core of daily life. Autonomous systems are revolutionizing agriculture, performing tasks like harvesting, planting, and crop monitoring, addressing labor shortages and boosting yields. In healthcare, domestically produced surgical robots perform complex procedures with high precision, while other robots assist in rehabilitation, automate pharmacy tasks, and transport supplies within hospitals, improving patient care and efficiency. Consumer robotics is also booming, with interactive humanoid and companion robots finding rapid adoption, showcasing market maturity and widespread societal acceptance of automation.

These diverse deployments signal more than just technological prowess; they represent the early fruits of a comprehensive national strategy. Though many systems are still maturing, their real-world application generates invaluable operational data, fueling rapid iteration, refinement, and cost reduction. China is already reaping the benefits through enhanced economic competitiveness and resilient supply chains. This accelerating feedback loop solidifies its lead, making advanced automation concrete reality today while much of the world remains focused on an automated future. The result is a widening a gap that becomes harder for the rest of the world to bridge with each passing day.

2. Why China is Serious About Robotics

China's meteoric rise in robotics is not merely a pursuit of technological prestige or economic gain. It stems from a potent cocktail of existential pressures: a shrinking workforce undermining its manufacturing core, complex geopolitical vulnerabilities threatening its resource lifelines, and deep historical lessons equating supply chain control with national survival. These factors converge into a single, undeniable reality for Beijing: automation is not an option, but the only viable path forward to secure its future independence and global standing. Understanding this intense motivation is key to grasping the scale and determination behind China's robotics strategy.

2.1. Cracks in Labor Foundation

China’s remarkable industrial ascent was built on the foundation of its seemingly inexhaustible workforce. However, the long-term implementation of the one-child policy altered this landscape, and now the nation grapples with a challenging demographic reality. An aging population is outpacing younger replacements, creating a labor shortfall that cannot be easily reversed. Efforts to boost fertility or entice new waves of rural migrants have largely fallen short. Many young professionals pursue digital entrepreneurship or higher education, often favoring flexible lifestyles over physically-demanding factory work. As this mindset spreads, China’s once-famed work ethic, symbolized by marathon shifts in its bustling manufacturing hubs, can no longer be taken for granted as a sustainable foundation for future economic growth.

This eroding labor foundation poses a serious threat to China’s long-established economic model. Factories that once thrived by attracting cheap, abundant labor are facing pressure to either rapidly automate or relocate to other regions with lower labor costs. If China's domestic manufacturing falters, it risks triggering a devastating domino effect on the intricate supply chains that feed over a billion consumers. The painful lesson from other industrialized nations is clear: once a country loses momentum in manufacturing, regaining that lost industrial base becomes a multi-generational struggle with lasting economic consequences. China has watched the hollowing-out of American industry with caution and recognized the destructive impact of overreliance on foreign suppliers.

Beijing sees a closing window to shore up industrial capacity before workforce challenges grow insurmountable. Rather than accepting factory migration or conceding to global competitors, policymakers view automation as a lifeline to preserve China's manufacturing output and satisfy the ever-growing demands of its massive domestic consumer market. By rapidly deploying robots, China aims to keep production lines humming, staving off the fate of other aging economies. Automation promises steady throughput, reduced error, and minimal downtime, offering an engine immune to demographic headwinds. The government’s unwavering push for mechanized production reflects a realization that labor-intensive manufacturing cannot remain competitive unless machines replace much of the human burden. This inflection point has become a national priority, galvanizing efforts to rebuild factories around robots to avoid sliding into industrial irrelevance.

2.2. Geopolitical Entanglements and Supply Chain Risks

China’s strategic outlook has long been shaped by its geography. It shares land borders with fourteen nations, many marked by past conflict or simmering tensions. Maintaining domestic stability means not only managing complex internal challenges – like ethnic diversity and vast regional inequalities – but also averting external threats from neighbors with clashing interests. This geopolitical tapestry includes nations such as India, Russia, Vietnam, and various states in Central Asia. Each border carries its own political baggage, from historical rivalries to resource disputes. For Beijing, managing these fractured relationships demands deft diplomacy, vigilant defense spending, and an acute awareness that strategic missteps can compromise its access to critical resources.

A prime vulnerability lies in energy supply. Much of China’s oil and gas imports pass through bottlenecks like the Strait of Malacca. The specter of foreign interdiction has haunted Chinese policymakers since the 1990s, prompting them to seek overland routes via Central Asia and Russia. Yet these avenues involve their own complications. China’s cordial ties with Russia mask a long history of territorial friction, and the development of energy corridors through Central Asian states require delicate negotiations with states that retain strong cultural and economic links to Moscow. Securing stable energy flows has thus become a top priority, fueling ambitious infrastructure projects like the China-Pakistan Economic Corridor and new pipelines from Turkmenistan. Beijing hopes these projects will reduce its vulnerability to maritime blockade and keep factories powered.

Adding to this volatility is the evolving relationship with the United States. Growing Sino-American tensions – trade disputes, technology bans, and mutual distrust – have forced China to confront the fragility of relying too heavily on Western suppliers. Economic sanctions can rapidly choke strategic imports, while heightened pressure from U.S. maritime assets can threaten energy routes at sea. In the eyes of China’s leadership, recent actions such as technology bans and export controls serve as sobering reminders of the extent to which the country remains reliant on high-end components, including advanced semiconductor chips, precision machinery, and sophisticated software, many of which are still sourced from Western nations. Decades of partial integration into the Western-dominated global technology ecosystem have undoubtedly brought significant economic prosperity to China but have also created a degree of dependency that Beijing now views as a critical strategic vulnerability.

Confronting these external pressures has nurtured a deep resolve for self-sufficiency. While the Made in China 2025 plan initially drew global attention for its focus on high-tech manufacturing, Beijing’s long-term goal of “dual circulation” reveals broader ambitions. By cultivating robust domestic industries and forging supply networks that bypass potential chokepoints, China seeks an economic model less susceptible to external shocks. Robotics serve as a crucial pillar in this quest. Though automated manufacturing, Beijing hopes to shield its industrial might from the uncertainties of global grade routes and foreign components. The more China automates, the less it depends on labor from beyond its borders or specialized hardware from hostile powers. This self-sufficiency imperative frames automation as an essential shield against geopolitical risks, intensifying the push toward a new industrial era.

2.3. The Mandate of History: Supply Chain Sovereignty

The confluence of a weakening labor pool and acute geopolitical sensitivities touches upon a deeply ingrained historical nerve for China: the existential threat of supply chain failure. Throughout its long and often tumultuous history, the collapse of powerful dynasties has often been precipitated not by external invasion alone, but by internal instability triggered by disruptions to essential supplies. For China, maintaining the integrity of its supply chains is therefore not just an economic imperative; it is intrinsically linked to national sovereignty, stability, and survival itself. It is a lesson etched into its collective memory through centuries of upheaval and dynastic transitions.

The fall of the technologically advanced Song Dynasty in the 13th century provides a vivid example. While facing the formidable Mongol armies, a critical factor in the dynasty's demise was the disruption of the Grand Canal, its primary internal artery for grain and resources. Mongol forces strategically blockaded key points along the canal, severing the flow of supplies to the capital and armies. The resulting shortages weakened defenses, fueled internal discontent, and ultimately contributed to the dynasty's collapse in 1279. Ironically, the Yuan Dynasty established by the Mongols later faced a similar fate when Ming forces employed blockades to cut off supplies to the Yuan capital Dadu (modern Beijing), hastening its fall in 1368.

More recently, the collapse of the Qing Dynasty, China's last imperial regime, was intertwined with a crippling monetary supply chain disruption. The dynasty had become reliant on silver imported primarily from Mexico for its currency system. The outbreak of the Mexican Revolution (1910-1920) severely curtailed silver production and exports. This sudden cutoff choked the Qing economy, triggering hyperinflation, widespread economic hardship, and social unrest. While the dynasty was already weakened by internal decay and foreign pressure, the silver crisis dealt a fatal blow, shattering its remaining authority and paving the way for its overthrow in 1912.

These historical precedents underscore a fundamental truth in the Chinese understanding of power: large empires are often undone from within, and the stability of supply chains is the bedrock of internal order. The memory of famines, hyperinflation, and societal breakdown resulting from disruptions of essential supply lines shapes a unique Chinese worldview that deeply values national stability, economic resilience, and comprehensive self-sufficiency. Millennia marked by recurring cycles of unity and chaos, periods of prosperity and hardship, have cultivated an introspective culture focused on balancing forces (reflected in the concept of yin and yang) and mitigating external dependencies.

Centuries of upheaval forged a worldview where true sovereignty means freedom from external dependencies for essential goods and technologies. In this context, supply chain sovereignty is national sovereignty.

In China, the concept of "freedom" often translates less to individual liberties as commonly understood in the West, and more towards national independence – specifically, the freedom from reliance on potentially unreliable or even hostile foreign powers for the very survival and prosperity of the nation. In this framework, supply chain sovereignty is national sovereignty. Dependency on external entities for essential goods and technologies is viewed as an inherent source of instability and an unacceptable vulnerability that leaves the nation's fate precariously in the hands of others. Leaving critical supply lines exposed to the unpredictable vagaries of international politics or the strategic chokepoints controlled by rivals is perceived an existential threat that must be actively and comprehensively neutralized.

Understanding this deep-seated drive for self-sufficiency clarifies many of China's major strategic initiatives over the past decades. The long-term energy contracts with countries like Iran and Russia, bypassing traditional sea lanes, aim to diversify energy imports away from vulnerable maritime chokepoints. The ambitious Belt and Road Initiative (BRI) aims create alternative land based trade routes to reduce reliance on sea lanes dominated by other naval powers. The massive state-driven investment in building a dominant electric vehicle and battery industry, encompassing the entire supply chain from extraction and refining of raw materials to manufacturing of batteries and vehicles, and even the recycling of end-of-life products, represents a strategic push to lessen dependency on foreign oil. Each move reflects a calculated effort to insulate China from external pressures and to secure control over its economic destiny in an increasingly uncertain global environment.

The world operates as an intricate dependency graph. True power lies in controlling access to the four foundational scarcities: raw materials, labor, energy, and technology.

Today, China is applying this same logic to the most fundamental input of all: labor. Recognizing the unavoidable constraints of its evolving demographics and the persistent risks of geopolitical friction, Beijing sees the comprehensive automation of labor as the next frontier in its quest for self-sufficiency and long-term strategic resilience.

2.4. Automation as the Final Frontier

For China, robotics is not a pursuit of prestige but a desperate bid for survival. The demographic crisis, unyielding despite policy shifts, leaves no room for half-measures or incremental adjustments. With a shrinking workforce and no viable path to repopulate its vast network of factories, China faces an unavoidable choice: automate or decline. Human-driven manufacturing, once the backbone of its remarkable rise, can no longer bridge the widening gap as millions retire and fewer step forward. Robotics offers the only escape, a means to decouple supply chains from demographics and secure the industrial might that feeds its massive population of over a billion people. This is not ambition, but a necessity and a lifeline to preserve sovereignty in a world that waits for no one.

China’s commitment is holistic and unwavering, a testament to its long-term vision. The Made in China 2025 initiative, launched in 2015, specifically earmarked robotics as a critical cornerstone, channeling over $300 billion into automation alongside AI, batteries, and high-speed rail. The 13th Five-Year Plan in 2016 set concrete targets – 50% automation in certain key industries by 2020, a goal China has largely achieved. By March 2025, a state-backed venture capital fund raised 1 trillion yuan (about $150 billion) from public and private sources, dwarfing investments elsewhere. This is not a scattered effort but a coordinated push, weaving together government, industry, and academia to build a robotics ecosystem from the ground up.

What sets China apart is its early and profound understanding of robotics not merely as a hardware engineering challenge but fundamentally as an intelligence problem. While other nations fixated on hardware, China’s technocrats – engineers turned policymakers – saw AI as the linchpin of true autonomy. In the early 2010s, China pivoted from a hardware-centric model to a massive investment AI, placing a calculated bet on software to unlock robotics’ true potential. The payoff is evident: firms like DeepSeek and SenseTime now rival global leaders as their algorithms power robots that adapt to chaotic environments. Though the U.S. still leads in AI sophistication, China’s growth is staggering, fueled by a decade of strategic patience and relentless execution. This shift reflects a rare clarity: automation’s future lies not in stronger gears but in intelligent machines that perceive, reason, and act autonomously.

China's decisive pivot to AI in the early 2010s revealed a rare strategic clarity: the future of robotics lay not in mechanics, but in machine intelligence.

China's forward-thinking approach draws a sharp contrast with nations like Japan and South Korea, hardware giants that stumbled in the robotics race. Japan’s ASIMO and SoftBank’s ventures dazzled but never scaled, trapped by a lack of AI focus and deployment vision. South Korea boasts high robot density – 932 per 10,000 workers in 2023 – but its machines remain caged and tethered to rigid tasks as they lack the intelligence for human-level adaptability. China’s willingness to reinvent itself, to bet on AI over legacy strengths, marks a decisive and perhaps, its most significant edge. Where others clung to past successes, China built a foundation for the future, aligning its industry to a singular goal: autonomy at scale.

This resolve positions China to dominate the coming era of automated labor. Robotics is the final piece in its self-sufficiency puzzle, a tool to eliminate labor as a vulnerability. By mastering automation, China aims to insulate its economy from demographic decline and geopolitical shocks, ensuring that its massive production capacity bends only to its own will and strategic imperatives. The scale of its investment and the depth of its strategy suggest a future where Chinese factories churn out goods with unmatched efficiency free from foreign influence. This is not a race for profit but a fundamental fight for independence, a mission to secure a nation’s destiny through the transformative power of intelligent machines.

China stands alone as a nation that has reinvented itself for the age of automated labor. From the ashes of a looming demographic crisis and the shadows of geopolitical peril, it has forged a robotics ecosystem that outpaces decades of U.S. progress in a mere ten years. Within two to three years, China will likely achieve mass deployment of general-purpose robots, true replacements for human labor, consolidating its lead in the most transformative shift in human history. As we turn to its robotics dominance, the world watches a nation poised to redefine the very fabric civilization through unrelenting automation.

3. The Rise of China's Robotics Ecosystem

China’s ascent in the robotics arena is not a fleeting triumph of technology but a deliberate march toward a fully automated supply chain. This march is powered by a vibrant ecosystem pulsing with innovation. This section unveils the tangible signs of that transformation, from a sprawling network of robotics companies to breakthroughs poised to redefine autonomy itself. Each element reveals a nation weaving self-sufficiency into its industrial fabric, positioning itself to lead the automated era while others scramble to catch up. What follows is a glimpse into the machinery driving China’s robotics revolution.

3.1. A Thriving Legion of Robotics Companies

China's robotics revolution is driven by a vast and dynamic ecosystem of companies – a living engine accelerating the nation's march toward a fully automated supply chain. This is not merely a collection of manufacturers but a sprawling network likely outnumbering the rest of the world's robotics firms combined. It represents a critical foundation of breathtaking breadth and depth for China's strategic ambition. Thousands of firms, from pioneers crafting sophisticated humanoids to specialists forging essential components, collaborate and compete, driving innovation at a scale unmatched elsewhere. This industrial density fuels China’s quest for supply chain sovereignty and redraws the global map of automation.

The ecosystem dazzles with its sheer variety, producing a catalog of robot types tailored for nearly every conceivable application. Thousands of companies churn out everything from affordable industrial arms like those from Siasun and Estun – rivaling Western counterparts in cost and performance – to advanced humanoid machines like Unitree's G1 or UBTech's Walker X. Drones from DJI dominate global markets, agricultural robots transform farming, medical systems assist surgeons, and logistics platforms from firms like Hikvision streamline warehouses. This diversity empowers China to tackle automation challenges across all sectors simultaneously, standing in stark contrast to the more niche focus often seen in Western robotics ventures.

Video: Unitree G1 Humanoid Kick-Up Demo

Beneath the surface of robot assembly lies a deep network of specialized firms crafting the building blocks of automation. Companies perfect sensors like RoboSense's LiDAR, actuators from Ningbo Zhongda Leader, dexterous hands from Linkerbot, and energy systems from giants like CATL. AI specialists like SenseTime and DeepSeek provide the intelligence layer. This modular structure enables robot makers to rapidly integrate high-quality components at competitive prices, bypassing the costly vertical integration burdening many US firms. Specialization drives costs down and quality up, turning the ecosystem into an efficient plug-and-play powerhouse that accelerates the entire field.

Its dense ecosystem, rich in specialization, allows China to rapidly iterate and drive down costs, creating an efficient powerhouse accelerating the entire field.

This intricate structure promotes remarkable resilience. With thousands of players, the ecosystem easily absorbs shocks that might cripple leaner industries. If one supplier falters, alternatives readily step in. Fierce competition ensures efficiency while accessible components lower entry barriers, preventing the industry from being dominated by a few vertically integrated giants – a potential risk in ecosystems lacking such depth. China deliberately cultivated this diversity, having learned from historical lessons about supply chain fragility and acting to avoid the concentration of power that could stifle innovation or create critical vulnerabilities. This allows the industry to scale rapidly without losing dynamism.

Ultimately, this thriving legion of companies forms the bedrock of China's robotics dominance. The ecosystem's unmatched scale, diversity, specialization, and resilience propel the nation toward industrial self-sufficiency. It creates an environment where innovation diffuses quickly, costs fall rapidly, and deployment scales massively. This intricate industrial machinery, built with strategic foresight and relentless execution, positions China not just to participate in the automated future, but to define its terms, setting a formidable benchmark for the rest of the world.

3.2. Technological Breakthroughs Igniting True Robotics

China's robotics dominance is increasingly powered by sophisticated domestic technology, shattering outdated perceptions of the nation as merely a follower. Years of focused investment and relentless execution are yielding significant breakthroughs across the entire robotics stack. Chinese companies, universities, and labs now generate innovations challenging global leaders, particularly in physical AI where the West long assumed enduring superiority. This technological surge reflects a holistic strategy treating robotics not as separate hardware and software problems, but as a deeply integrated intelligence challenge. The pace of progress is accelerating, rapidly closing the gap with – and in some areas defining – the global frontier.

The journey toward true labor replacement hinges on hardware replicating human capabilities, and China's ecosystem is delivering. Domestic firms like Orbbec produce advanced 3D vision systems offering high-fidelity depth perception at competitive prices, while others push sensor resolution for precision tasks. Tactile sensing is advancing rapidly – flexible, high-resolution arrays are available, while neuromorphic sensors mimicking human touch are emerging from labs. While some high-end motors are still imported, domestic players like TPA Robot are producing increasingly capable actuators vital for dexterity and safe interaction. Leveraging their battery supremacy, CATL and BYD provide specialized, high-density power sources that enable longer robot endurance.

Video: CoA-VLA (Vision-Language-Action via Chains of Affordances)

While hardware provides the body, physical AI bestows the intelligence for true autonomy. China's progress here is explosive. Researchers are pioneering powerful foundation models like Vision-Language-Action models (VLAs) that enable robots to understand complex commands and interact intuitively with the world. Examples like RoboMamba from Peking University or AgiBot's GO-1 demonstrate sophisticated capabilities learned from vast datasets, often collected from China's own large-scale deployments. These models integrate perception, reasoning, and action, moving robots beyond pre-programmed routines towards genuine adaptability in unstructured environments.

China's explosive progress in physical AI demonstrates a core understanding: true autonomy arises from integrated intelligence, not just capable hardware.

Video: AgiBot’s GO-1 Operator Model

This AI advancement is built on integrating multiple learning paradigms. Reinforcement Learning (RL) techniques are being refined for greater efficiency, while Imitation Learning (IL) allows robots to acquire complex skills rapidly by observing human demonstrations, as seen in systems from companies like PsiBot. Large Language Models (LLMs) are leveraged for advanced reasoning and planning, enabling robots to break down high-level goals into executable steps and handle unforeseen situations. Chains of Affordances (CoA) use fundamental action units (affordances) to allow smooth transitions between subtasks. Sophisticated simulation environments and world models are also being developed, allowing faster, safer training and testing, further accelerating the path to robust real-world performance.

The synergy between rapidly advancing hardware and accelerating physical AI creates a formidable innovation engine. Breakthroughs are not confined to labs but are quickly integrated into deployed robots, generating operational data that fuels a powerful feedback loop. While the US may retain an edge in some frontier AI research, China's velocity, its focus on practical integration, and its sheer scale create a unique competitive dynamic. China is no longer just catching up; it is becoming a primary architect of the core technologies shaping the automated future.

3.3. Gearing Up for Mass Production Through Standardization

Technological breakthroughs and a legion of companies provide the raw power for China's robotics ascent. However, translating this potential into efficient, scaled production hinges on standardization. Creating common rules, interfaces, and protocols across hardware, software, and processes is the essential lubricant allowing the entire industrial engine to achieve mass deployment. Fragmentation breeds inefficiency and costly vertical integration, hindering the widespread adoption that defines a true industrial revolution. Navigating the fine line between imposing order and chaos requires deep technical insight and precise timing. China’s approach, guided by technocrats and fostered through state-industry dialogue, cultivates standardization deliberately, preparing its ecosystem for the era of mass automated production.

Hardware standardization forms the physical bedrock for scale. Government bodies like MIIT issue clear directives, such as the 2023 humanoid robot guidelines, mandating standardized critical components like motors, sensors, and control systems to enable mass production by 2025. National initiatives and innovation hubs reinforce this push. The Beijing Robotics Innovation Center's "Tiangong" humanoid platform offers an open-source blueprint with standardized interfaces, accelerating development across the industry. Private firms actively align, adopting modular designs like Fourier N1, while component makers like Hikrobot achieve economies of scale. This drives down costs, incentivizes broader adoption of common parts, and ultimately builds a resilient domestic supply chain.

Video: Fourier N1 (Open Source Humanoid by Fourier Intelligence)

Intelligent robots demand coherent software, and China recognizes standardizing this layer is vital for unleashing physical AI and ecosystem collaboration. Efforts focus on common middleware, interoperable AI models via standardized APIs, robust cloud platforms from giants like Huawei, shared simulation environments, and domestic operating systems like Beijing's "Huisikaiwu" (OpenHarmony + ROS). National AI guidelines encourage data format and protocol consistency. Initiatives like the National Humanoid Robot Innovation Center’s data-sharing platform create pooled datasets and accelerate AI model training across the ecosystem. This collaborative software foundation allows innovations to propagate rapidly and makes China's robots smarter at an accelerating pace.

China's deliberate cultivation of common standards across hardware, software, and process reveals a coordinated strategy to eliminate fragmentation and accelerate automation.

Beyond the robots themselves, China standardizes the process of automation, leveraging its vast manufacturing base and deep field expertise. Government bodies and industry associations like CIRA establish best practices for deployment, integration, safety, and maintenance. They codify the know-how gained from extensive real-world application to create repeatable templates for automation. Leading manufacturers offer standardized work cells to simplify adoption. This systematic approach translates tacit operational knowledge into formal processes, which shortens implementation times, reduces risks, and maximizes efficiency gains across industries, thereby accelerating the nation's transition to a fully-automated supply chain.

China's multi-faceted standardization drive is a masterclass in industrial strategy. By meticulously aligning hardware, software, and process optimization, Beijing constructs the essential infrastructure for mass automated production and deployment. This deliberate, collaborative effort weaves together government direction and industry execution, creating a powerful synergy absent in more fragmented Western ecosystems. It is not standardization for its own sake but a calibrated strategy enabling efficiency, reducing costs, and ensuring interoperability. This positions China not just to lead but to define the operational playbook for the global robotics revolution, solidifying its path toward unparalleled industrial scale and supply chain sovereignty.

3.4. End-to-End Supply Chain Dedicated to Robotics

A robot alone achieves little. True industrial transformation requires an intricate support web covering production, deployment, and sustained operation. This dedicated supply chain turns advanced machines from prototypes into reliable engines of automation. China uniquely understands this necessity and is meticulously constructing a comprehensive robotics supply chain that underpins its global lead. This system is rapidly maturing toward the mass deployment of genuine labor replacements, solidifying China’s path toward unparalleled productivity and strategic autonomy. Other nations find themselves increasingly reliant on this engine, a dependency built on China’s foresight and relentless execution over the past decade.

Success in robotics rests upon an end-to-end supply chain supporting the entire automation lifecycle.

China’s robot manufacturing capacity has become colossal, cementing its role as the world’s primary builder of automation hardware. In 2023 alone, the nation produced a staggering 430,000 industrial robots and over 7.8 million service robots, dwarfing output elsewhere. This explosive growth is driven by strategic government backing like Made in China 2025, massive domestic demand, and a maturing local component base. Critically, domestic manufacturers now command nearly half of China’s vast internal market, showcasing a powerful shift toward indigenous capability. This immense production scale provides the physical foundation for China’s automation ambitions and is a crucial step toward supply chain sovereignty.

Beyond sheer production, China is building the vital infrastructure to keep its enormous robot fleets operational. Effective maintenance demands readily available spares, skilled technicians, and efficient service logistics – areas where China excels by leveraging its deep manufacturing base and fostering specialized service providers. National standards bodies codify maintenance protocols and integrate predictive systems powered by operational data. This unified approach ensures hardware investments translate into sustained productivity, contrasting sharply with fragmented service networks elsewhere that hinder widespread adoption. This operational resilience forms a critical, often overlooked, layer of China’s advantage, ensuring robots deliver value long after deployment.

Video: China’s World’s Most Advanced Robot Warehouse (AI Automation)

Efficient operation also requires sophisticated management systems, another area of Chinese strength. Advanced fleet management software enables real-time tracking, automated task assignment, performance monitoring, and centralized diagnostics across large deployments. Companies like JD.com coordinate hundreds of autonomous mobile robots in complex warehouses using systems that dynamically optimize routes and workflows. AI-powered platforms analyze operational data to identify bottlenecks, predict failures, and enable proactive intervention. This mastery over managing large-scale operations of robot fleets forms the invisible backbone of China's automation push, enhancing reliability and maximizing the efficiency gains from its deployed fleets.

Ultimately, China’s dominance arises from constructing a nearly-complete, full-stack robotics ecosystem. This encompasses control over essential inputs – from raw materials like rare earths and increasingly capable domestic chips to specialized components, advanced sensors, powerful actuators, and the sophisticated physical AI software driving autonomy. Supported by vast manufacturing infrastructure and coordinated national initiatives, this deep integration creates a seamless value chain from design to deployment, rapidly propagating innovations across the growing ecosystem. This unique, integrated capacity to orchestrate the entire robotics industry paves China's winning path toward technological self-sufficiency and national independence.

3.5. Continuous Innovation Through Real-World Feedback

China accelerates its robotics evolution through a potent feedback loop unlike any other: aggressive real-world deployment fused with structured knowledge sharing. This is not innovation confined to sterile labs but a dynamic cycle where robots, even imperfect ones, are pushed into complex operational environments. Factories, farms, and city streets become crucibles generating invaluable data. This pragmatic approach that treats early challenges not as failures but as catalysts demands close coordination and a strong will to learn. China's mastery in orchestrating this intricate dance between deployment and collaboration fuels its ecosystem's unmatched velocity, propelling it forward while others refine prototypes in isolation.

Video: Tech Hub Shenzhen Leads China’s Robotics Revolution

This philosophy manifests in a strategy of rapid, large scale deployment. China understands that physical AI can advance only through the unpredictable chaos of reality. Early stage robots are everywhere: sorting bots populate JD.com's logistics hubs, SF Express tests delivery vans on urban streets, agricultural fields trial automated harvesters, and hospitals experiment service bots from companies like Pudu Robotics. Imperfection is accepted as the price for crucial insights into performance limits, failure modes, and human interaction challenges under real conditions. This direct feedback allows hardware and physical AI models to be rapidly refined against actual operational demands beyond theoretical benchmarks.

Robotics companies that deploy aggressively harden systems against real-world rigors far faster than those focused on achieving perfection before deployment.

Video: China Unveils First Humanoid Robot Training Base in Shanghai

Complementing this aggressive deployment is a deliberate push to build platforms for shared learning. China recognizes collective progress vastly outpaces isolated efforts, so it fosters environments where companies, researchers, and government bodies systematically exchange knowledge, pool operational data, and collaboratively forge standards. This network effect minimizes redundant work and allows the entire ecosystem to benefit from individual breakthroughs. Shared resources like Shanghai's Humanoid Robot Kylin Training Ground, national innovation centers, industry alliances such as CRIA, and open source initiatives like OpenLoong create a powerful multiplier effect, accelerating innovation across the board.

Combining rapid deployment with structured collaboration and shared learning creates an unparalleled innovation engine.

This unique blend of rapid deployment and structured collaboration creates an unparalleled innovation engine. Real-world data from widespread use cases feeds into shared platforms, generating insights that accelerate refinement for the next wave of deployment. While companies compete fiercely, they simultaneously participate in a shared infrastructure lifting the entire ecosystem. This combination of government guidance, industry collaboration, and pragmatic learning from real-world application transforms isolated advancements into systemwide progress. It is the core mechanism driving China’s accelerating lead in the global robotics race that continuously widen the gap with the rest of the world.

China's robotics ecosystem is a testament to deliberate strategy and relentless execution. At its core lies a vast legion of companies fueled by domestic technological leaps and structured by careful standardization. This is supported by an increasingly self-sufficient supply chain and accelerated by a unique innovation cycle of rapid deployment and shared learning. It is an industrial machine built with foresight over a decade that positions China not merely to participate in the automated future, but to dictate its terms through unparalleled scale and accelerating momentum.

4. Fueling the Ascent: The Power of State-Civil Harmony

Building a robotics ecosystem capable of genuine labor replacement is monumentally complex. It demands simultaneous breakthroughs in diverse technologies, coordinated deployment across countless sectors, intricate supply chain orchestration from minerals to AI, and meticulous execution amidst deep uncertainty. China’s rapid success defies conventional explanations of population size or resource abundance. Its meteoric rise stems from a deeper source: an unprecedented state-civil harmony, where government and private enterprises collaborate intensely toward the shared goal of national self-sufficiency through full-scale supply chain automation. This synergy, a powerful engine forged over decades, is the crucial element fueling China's robotics fire.

4.1. A Stabilized Political Landscape

Contrary to common Western perceptions of a monolithic regime, China’s political landscape is a complex tapestry woven from competing factional interests and navigated through consensus building. No single individual or clique wields absolute power; even President Xi Jinping operates within a system of checks, balances, and consultations with party elders and military figures. His third term, often misinterpreted in the West as simple power consolidation, emerged from intricate internal negotiations – a compromise preferred by rival factions over installing a handpicked successor who might ensure longer dominance for Xi's group. This outcome reflects the Byzantine nature of Chinese elite politics that prioritizes stability above all else.

Political continuity provides the essential long-term stability required for executing ambitious, multi-decade technological endeavors.

This resulting political continuity, confirmed in 2022, ironically provided a powerful tailwind for China's complex technological ambitions, particularly in robotics. Avoiding the internal friction, leadership reshuffles, and policy discontinuities that often accompany power transitions allowed competent technocrats within the Chinese government – from central ministries to provincial bureaus – to maintain focus and momentum on long-term strategic projects. With reduced political turbulence, officials could dedicate their energy to execution, benefiting from President Xi's apparent shift towards delegating detailed oversight while retaining strategic direction. This stability fostered an environment conducive to sustained, complex national initiatives.

A government deeply embedded with technocratic expertise possesses the unique capacity to navigate and drive complex national projects like full-scale automation.

The impact of this stability is amplified by the deep-seated technocratic nature of the Chinese government, further reinforced under the current leadership. Key figures like Premier Li Qiang and Vice Premier Ding Xuexiang possess strong pro-technology track records, heading a vast bureaucracy populated with engineers and scientists across crucial bodies like the NDRC, MIIT, and MOST, extending down to local levels in tech hubs like Shanghai. When this technical expertise and relative political calm aligned with the national imperative for automated self-sufficiency, it unleashed formidable energy, preparing the ground for the remarkable state-civil harmony driving the robotics revolution.

4.2. Skilled Diplomacy and Resource Security

China’s robotics ambitions are underpinned by a diplomatic strategy characterized by patience, continuity, and meticulous long-term planning – a stark contrast to the often fragmented, election-bound initiatives seen in the West. Beijing’s foreign policy consistently prioritizes securing the strategic resources essential for industrial independence and supply chain resilience. Recognizing automation as vital to national destiny, China has tirelessly maneuvered for years to ensure its burgeoning robotics industry has reliable access to critical inputs like rare earths, lithium, cobalt, and stable energy. This relentless focus creates tangible advantages for domestic firms, demonstrating a powerful harmony between statecraft and industrial strategy that prepares the nation for the automated era.

In Myanmar, China executed a complex diplomatic play following the 2021 coup, skillfully navigating the ensuing civil conflict. Reports suggest Beijing subtly backed three anti-junta ethnic armed groups in northern Myanmar, leveraging the ethnically-Chinese Kokang army as a conduit to coalesce the "Brotherhood Alliance". This support allegedly triggered the "Operation 1027" that dismantled the pro-Russia and junta-aligned forces controlling key border trade zones. Simultaneously, China conducted border military exercises, discouraging a full junta counter-offensive while remaining silent when the Brotherhood Alliance faced pressure from hostile armed factions. This carefully-managed escalation created mutual desperation for a ceasefire. China then stepped in as the indispensable mediator, reportedly securing significant concessions including critical access to contested northern rare earth deposits, vital for high-performance robotics components.

Years before the chaotic American withdrawal from Afghanistan, China adopted a long-term pragmatic approach toward the Taliban, maintaining communication channels even when the group was an insurgency. After the Taliban's return to power in 2021, while Western nations evacuated and imposed sanctions, Beijing kept its embassy open, provided crucial humanitarian aid, and engaged in high-level diplomatic meetings. This strategic engagement built critical trust and stability that positioned Chinese state-owned companies like MCC to reactivate dormant contracts signed with the previous Afghan government. The prize was access to Afghanistan's untapped mineral wealth with the estimated value of $1 trillion, including vast deposits of lithium, copper, iron ore, and rare earths – essential inputs for scaling China's robotics and EV industries – reliably sourced from a cooperative neighbor, reducing reliance on distant, potentially unstable sea lanes.

In Indonesia, Beijing skillfully aligned itself with Jakarta’s "downstreaming" initiative, a high-stakes policy aimed at building domestic processing capacity for its rich nickel and cobalt reserves rather than merely exporting raw materials. Indonesian policymakers pushing this agenda faced immense pressure and needed tangible successes. While Western firms balked at the investment risks and uncertainties, Chinese companies poured billions into building smelters and industrial parks like Morowali. This provided the capital, technology, and political backing Jakarta desperately needed to ensure the policy's viability. In return, Chinese firms secured unparalleled access to the world's largest reserves of nickel, vital for high-performance batteries. This approach yielded not just resources, but deep political partnerships with Indonesian officials whose careers were advanced by China’s timely intervention, ensuring long-term resource security for its robotics ambitions.

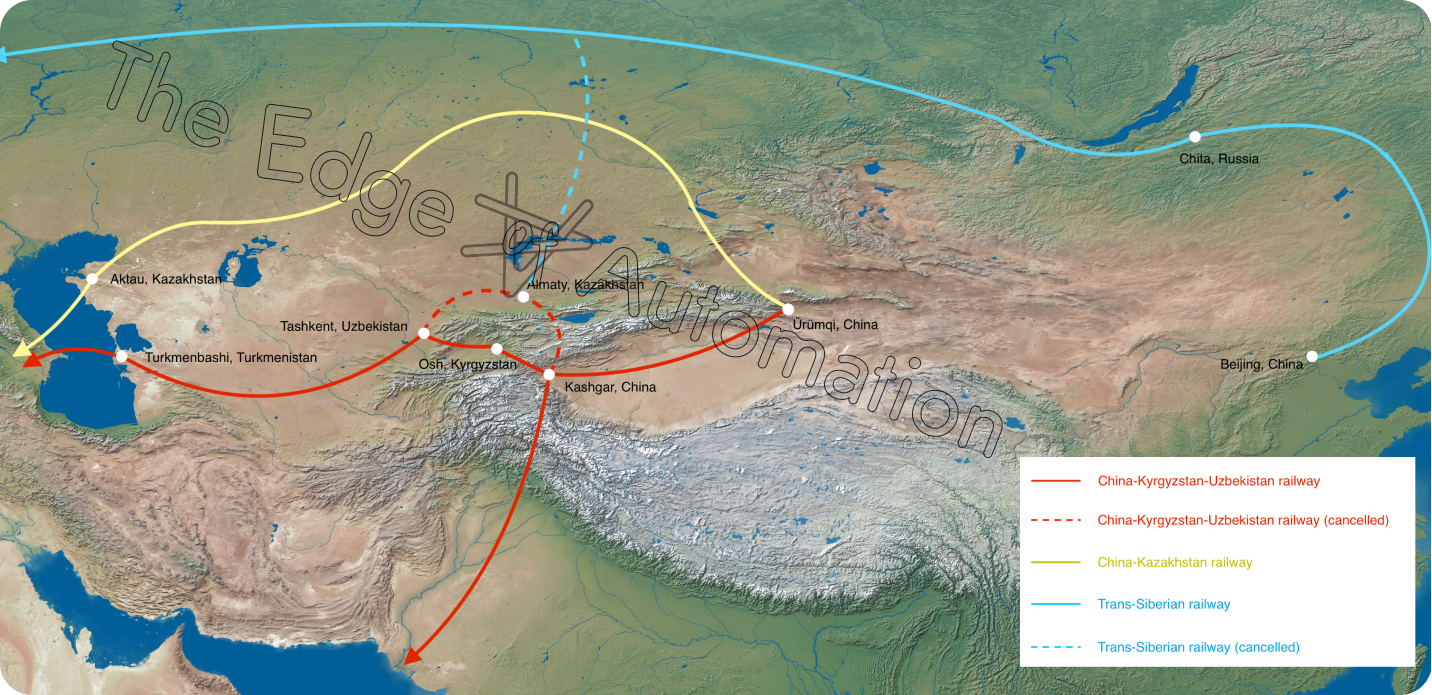

China also masterfully leveraged shifting geopolitical tides in Central Asia to advance the long-stalled China-Kyrgyzstan-Uzbekistan (CKU) railway. Russia had long resisted Chinese influence in inland Asia, favoring northern corridors to protect its regional interests. However, facing increased isolation after the invasion of Ukraine and witnessing shifts in Kazakhstan's alignment, Moscow's leverage diminished. Beijing seized this opportunity, navigating complex multi-party negotiations to finally secure agreement on its preferred southern route. This vital infrastructure provides a direct, overland rail link to Central Asia, the Middle East, and potentially Europe, bypassing maritime chokepoints like the Strait of Malacca while securing more reliable, faster import for energy and regional resources. The result was a strengthened the logistical backbone supporting China's manufacturing and high-tech industries, including its resource-intensive robotics sector.

Even apparent setbacks were deftly managed, as demonstrated by Malaysia's East Coast Rail Link (ECRL). When the new Malaysian government threatened cancellation of the multi-billion dollar Belt and Road Initiative (BRI) project due to high costs and sovereignty concerns inherited from its previous administration, China opted for pragmatic renegotiation over confrontation. Engaging in protracted talks, Beijing agreed to slash the project's cost by nearly a third while adjusting operational terms to ensure its continuation. This flexibility preserved a crucial transportation corridor across the Malay Peninsula, enhancing regional connectivity aligned with BRI objectives. More importantly, it reinforced China's image as a reliable, adaptable long-term partner committed to seeing projects through, fostering regional goodwill crucial for future resource deals and infrastructure initiatives supporting its expanding economic footprint.

These diplomatic successes aren't isolated incidents but facets of a coherent, long-term strategy rooted in a deep, civilizational understanding of geopolitics centered on supply chain sovereignty. China perceives the world as an intricate dependency graph and skillfully navigates it to minimize external vulnerabilities. This approach, reminiscent of historical Chinese statecraft managing peripheral powers, leverages economic influence, demonstrates strategic patience, and focuses relentlessly on the foundational elements of national power – reliable access to resources and control over critical supply lines. This mastery of the long game, focused on securing the raw materials and logistical pathways needed for advanced manufacturing, reveals a crucial, often underestimated, foundation for China’s dominance in robotics.

4.3. Strong Foundation for Technology Industry

The strategic resources secured through skilled diplomacy flow into an exceptionally fertile domestic technology landscape, creating the conditions for rapid innovation in robotics. This foundation rests not just on capital or infrastructure, but critically on human capital and a dynamic industrial culture. China possesses an unmatched reservoir of engineering talent, cultivated through massive educational investment and cultural reverence for technical expertise. This talent pool operates within a fiercely competitive yet accessible market that fosters rapid iteration and a unique ability to pivot into new technological frontiers like physical AI. The result is a dramatically accelerating the timeline for the emergence of truly capable robots and China's supply chain sovereignty.

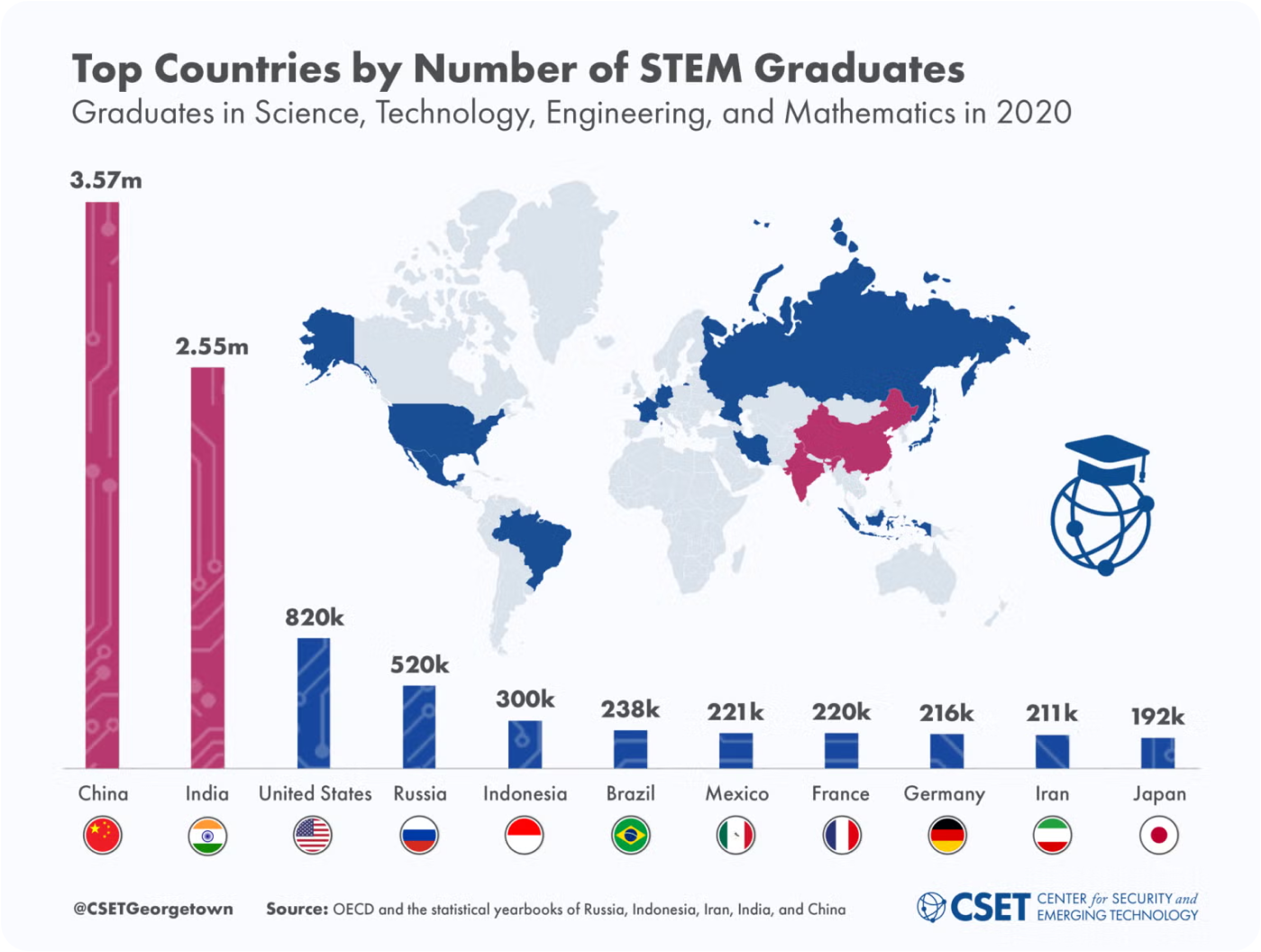

The sheer scale of China's engineering workforce provides a fundamental advantage. Each year, Chinese universities graduate millions of STEM students, dwarfing the output of the United States and feeding a vast pool of capable, often highly driven, mid-level engineers. While the US may still lead in elite, top-tier researchers, China benefits immensely from this broad base of technical skill available at a competitive cost. This deep talent pool fuels both established tech giants and countless startups tackling complex robotics challenges, from sensor design to AI algorithms, providing the necessary manpower for large-scale R&D and deployment efforts.

China's thriving engineering community operates within an environment characterized by remarkably low entry barriers and hyper-competition, often termed "neijuan" or involution. The accessibility of components from the vast domestic supply chain, coupled with readily available manufacturing expertise and government support programs, allows new robotics ventures to spring up relatively easily. This fuels intense competition that forces companies to iterate rapidly, optimize relentlessly for cost and performance, and seek out practical go-to-market applications quickly. This "Red Queen" effect, where companies must run faster just to stay in place, drives efficiency and accelerates the overall maturation of the robotics sector at a pace difficult for less competitive ecosystems to match.

Furthermore, Chinese tech companies exhibit an extraordinary willingness and ability to pivot into adjacent or entirely new domains, a flexibility crucial for a nascent field like robotics. Tech giants originally focused on e-commerce (Alibaba), search (Baidu), social media (Tencent), or food delivery (Meituan) have all made significant, often surprising, investments in robotics R&D and deployment, leveraging their existing scale, data, and capital. Smartphone maker Xiaomi has become a major player through investments and its own CyberDog and CyberOne projects. This cross-pollination injects diverse expertise and resources into the nascent robotics ecosystem, accelerating progress in ways that more siloed industries struggle to replicate.

This potent combination – abundant and driven engineering talent, a low-friction yet hyper-competitive market, and a culture of bold pivoting – creates an industrial dynamism ideally suited for conquering the complexities of robotics. It is an environment where ideas can be rapidly tested, scaled, and refined, powered by a workforce eager to tackle the challenges of automation. This strong technological foundation, built through decades of focused effort by both state and industry, provides the essential human engine for China’s robotics revolution, turning strategic vision into tangible reality and propelling the nation toward its goal of self-sufficiency.

4.4. A Truly Full-Stack Supply Chain

China’s ultimate strategic advantage, the bedrock upon which its robotics ambitions rest, is its unparalleled national supply chain. This isn’t merely a collection of factories, but a deeply integrated, comprehensive industrial ecosystem supporting virtually every sector imaginable, from raw material extraction to sophisticated component manufacturing and advanced AI development. China's burgeoning robotics industry is meticulously woven into this vast network, drawing immense strength from its unique density, scale, and increasingly self-sufficient capabilities. Today, China stands alone as the only nation possessing a truly full-stack supply chain largely contained within its own borders. As true robots emerge from prototypes into commercial reality, this industrial engine provides an unmatched foundation, poised to amplify the coming automation wave and solidify China’s dominance into an unassailable strategic position.

The sheer breadth and depth of this supply chain are historically unprecedented. China manufactures everything from basic textiles and toys to advanced electronics, high-speed rail, electric vehicles, and sophisticated industrial machinery. Crucially, it also produces the vast majority of the components required for these products domestically. This comprehensive coverage means robotics companies can source nearly everything they need – specialized alloys, precision motors, advanced sensors, processors, batteries – from within the country, often from multiple competing suppliers. While reliance on foreign sources for some high-end components like harmonic gear reducers persists, domestic firms are rapidly closing gaps, supplying coreless motors, advanced sensors, and entering the supply chains of major international players. This minimizes reliance on foreign imports, reduces logistical friction, accelerates development cycles, and lowers costs, giving Chinese robotics firms a structural advantage unavailable elsewhere.

This comprehensive industrial fabric is supported by world-class physical and digital infrastructure, built out over decades of sustained national investment. China boasts the world's largest high-speed rail network that exceeded 48,000km by the end of 2024, alongside modern highways connecting all major economic hubs. Its ports, including global leaders like Shanghai and Ningbo-Zhoushan, handle staggering cargo volumes with a combined total of over 280 million TEU containers in the first eleven months of 2023. Furthermore, accelerating deployment of 5G networks and cloud data centers enhances overall productivity and nurtures growth of China’s digital economy. This sophisticated infrastructure connects the disparate parts of the supply chain, enabling efficient production and creating the perfect testing ground for large-scale robot deployment in complex, real-world operational settings.

Possessing a truly full-stack supply chain within its borders grants China a structural advantage, minimizing external reliance and amplifying the impact of automation.